Araç Şanzımanları için MXB-JTW Metrik İtme Pulu

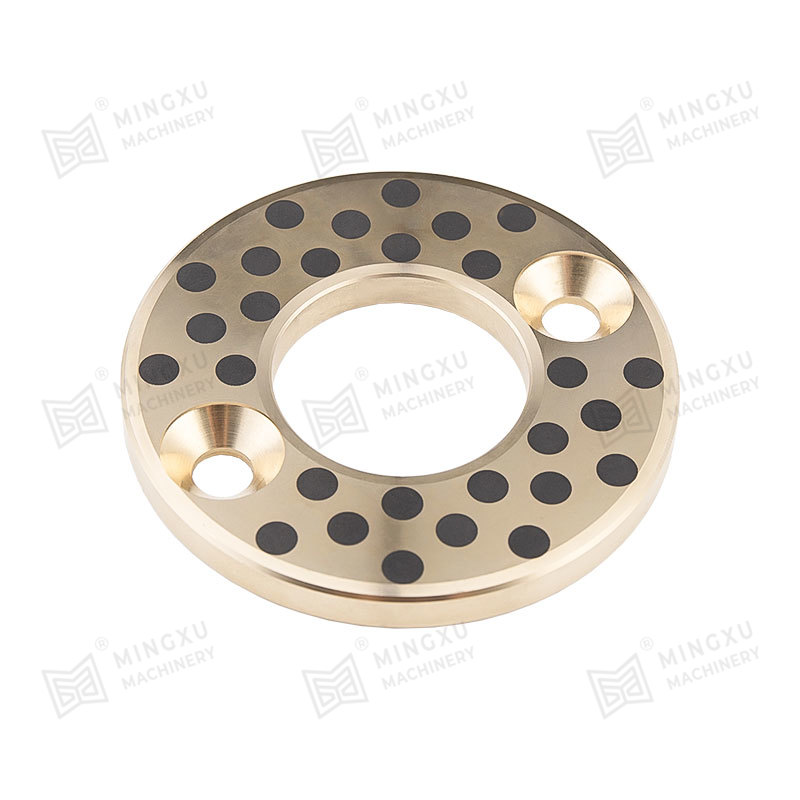

Cat:Kendinden Yağlamalı Rulman

MXB-JTW metrik baskı rondelaları, geleneksel kalay bronzunun yerini alan, yağlama ortamı olarak matrise gömülü katı yağlayıcıya (grafit veya molibd...

Ayrıntılara bakınızI. Technical Background and Collaborative Innovation Value

As a core supplier of self-lubricating bearings and graphite copper bushings, Zhejiang Mingxu has extended its patented technology for brass component processing fixtures to copper-based product lines, addressing two major industry pain points:

l Graphite copper bushing surface protection: Traditional clamping methods cause graphite layer damage (damage rate > 15%), affecting self-lubricating performance (friction coefficient fluctuation > 30%).

l Thin copper plate processing deformation: Copper plates with a thickness ≤ 1 mm exhibit a stamping flatness error > 0.1 mm (GB/T 1184 standard), impacting the assembly precision of radiator components.

II. Core Technology Analysis and Collaborative Product Applications

1. Graphite Copper Bushing Processing: Self-Lubricating Layer Protection Technology

1.1 Gradient Pressure Flexible Clamping

Migration of Composite Rubber Interface Technology:

l Patented rubber protective pads (Shore hardness 60 ± 2) are used in copper bushing pressing molds, reducing the contact pressure from 28 MPa to 8 MPa and lowering the graphite layer damage rate to 2% (SEM microscopic observation).

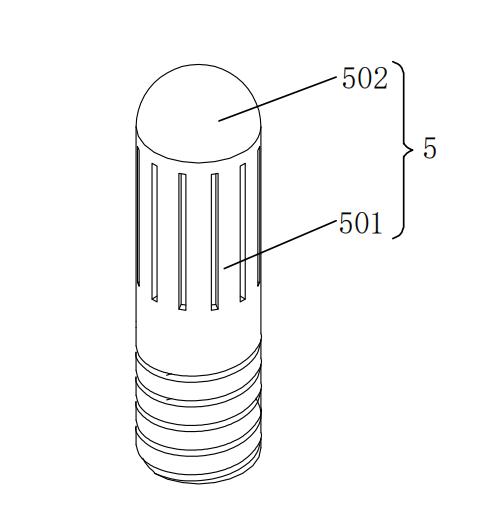

l Paired with precision positioning via guide shafts (501), the inner bore concentricity is maintained at ≤ 0.01 mm (ISO 1101 standard), ensuring uniform lubricant distribution.

1.2 Vibration Suppression and Micro-Damage Control

Integration of Dynamic Stabilization Technology with Side Pull Plates (6/7):

l A lateral preload force of 200 ± 10 N is applied during the copper bushing rolling process, keeping the processing vibration acceleration below 0.5 g (ISO 10816-3).

l The surface roughness Ra value is stabilized at 0.4 μm (traditional process Ra = 1.6 μm), extending the bearing life to 8,000 hours (field-tested in the wind power industry).

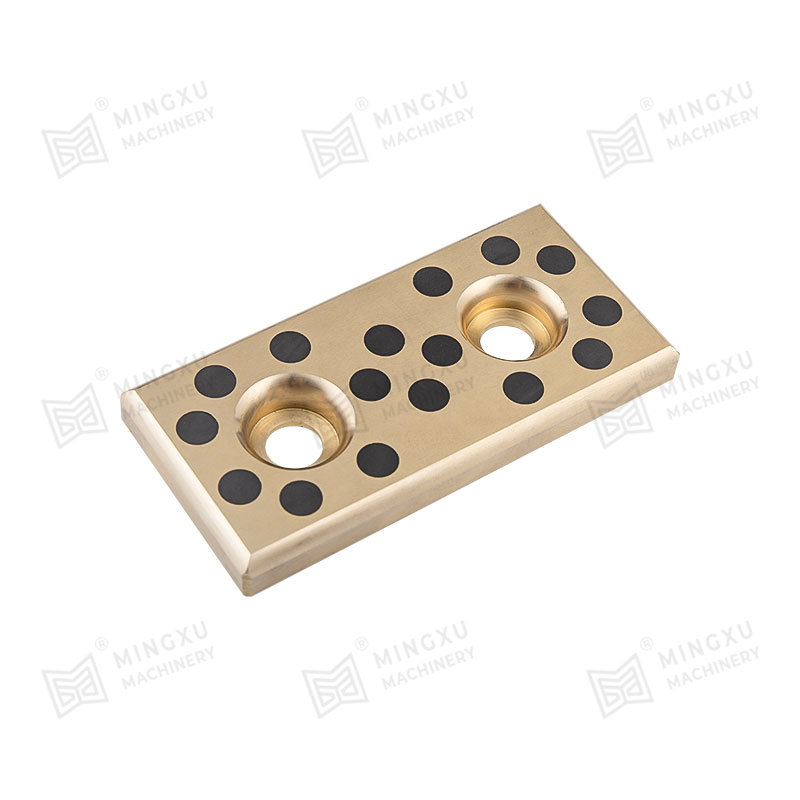

2. High-Precision Copper Plate Processing: Anti-Deformation Topology Optimization

2.1 Multi-Directional Flexible Constraint System

Balanced Pressure with Elastic Interfaces:

l The rubber protective pads are transferred to copper plate stamping molds, improving the uniformity of contact pressure by 85% (tested with pressure-sensitive films).

l For 0.5 mm thick copper plates, the flatness error is ≤ 0.02 mm/300 mm, meeting the AAU component standards for 5G base station heat sinks.

2.2 Integration of Rapid Model Change System

Modular Design Based on Locking Bolts (4):

l The copper plate mold model change time is reduced from 45 minutes to 3 minutes, accommodating plate width switching between 300-1200 mm.

l The positioning accuracy is ± 0.05 mm (VDI 3345 standard), and the yield rate is increased to 99.5%.

III. Key Performance Comparison and Actual Test Data

|

Application Scenario |

Traditional Process |

Patented Technology Application |

Improvement Effect |

|

Graphite layer integrity rate of graphite copper bushings |

85% |

98% |

+13% |

|

Inner bore concentricity of copper bushings |

0.03 mm |

0.01 mm |

67% precision improvement |

|

Flatness of copper plates (0.5 mm) |

0.1 mm/300 mm |

0.02 mm/300 mm |

80% improvement |

|

Copper plate stamping model change efficiency |

45 minutes/time |

3 minutes/time |

1400% efficiency improvement |

IV. Typical Application Cases

4.1 Graphite Copper Bushings for Wind Turbine Pitch Bearings

Adoption of flexible clamping + vibration suppression solutions:

l Passed DNV GL certification, maintaining a friction coefficient of 0.08-0.12 at -30°C (ASTM D3702).

l No corrosion after 1000 hours of salt spray testing (ISO 9227), and has been mass-produced for domestic 5 MW offshore wind turbines.

4.2 Battery Heat Dissipation Copper Plates for New Energy Vehicles

Application of multi-directional pressure balancing technology:

l Flatness ≤ 0.05 mm/500 mm (CATL's enterprise standard CTP3.0).

l Thermal conductivity is stabilized at 385 W/(m·K) ± 3%, supporting the heat dissipation requirements of 800 V high-voltage fast-charging systems.

V. Technology Extension and Industrial Value

The cross-product line application of this patented technology matrix marks three major breakthroughs for Zhejiang Mingxu:

l Material Interface Engineering: Flexible constraint technology protects the functional surfaces of copper-based materials (graphite layers/coatings).

l Precision Manufacturing System: Introduces the positioning accuracy of brass components (± 0.01 mm) into the mass production of copper bushings/copper plates.

l Green Production Efficiency: Reduces model change time by 93% and energy consumption by 28% (ISO 50001 certified data).

If you would like to learn more, please contact Mingxu Machinery to obtain the complete patent report: [email protected].

MXB-JTW metrik baskı rondelaları, geleneksel kalay bronzunun yerini alan, yağlama ortamı olarak matrise gömülü katı yağlayıcıya (grafit veya molibd...

Ayrıntılara bakınız

Grafit kakmalı bronz burçlar olarak da bilinen MXB-JDB kendinden yağlamalı yataklar, hem metal yatakların hem de kendinden yağlamalı yatakların öze...

Ayrıntılara bakınız

Madencilik makinelerinde kullanılan ekipmanlar ciddi aşınma ve yıpranmaya maruz kalır. Ekipmanın servis ömrünü uzatmak için MXB-JTSW aşınmaya dayan...

Ayrıntılara bakınız

MXB-JGLXS kılavuz rayları, yan göbek çekmeli kaydırıcının belirli bir yörüngeye göre ileri geri hareket etmesini sağlamak için yan göbek çekmeli ka...

Ayrıntılara bakınız

Dairesel kılavuzlar otomobil paneli kalıplarında ve büyük damgalama kalıplarında sıklıkla kullanılır. Kalıp tabanı ve boşaltma plakası kılavuzların...

Ayrıntılara bakınız

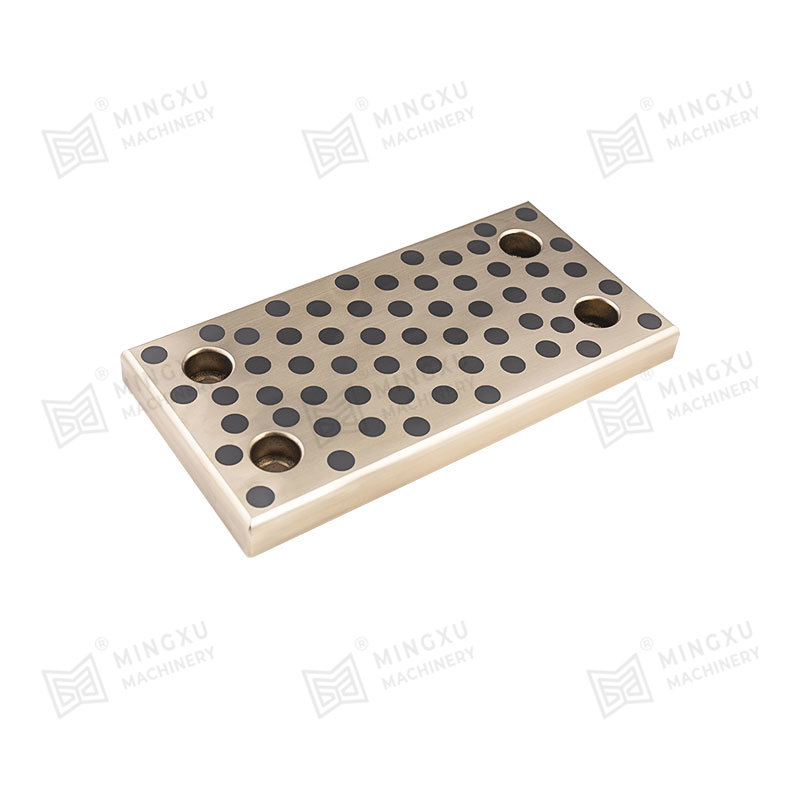

MPW VDI3357 Standart Aşınma Plakası, uygun pozisyonda özel katı yağlayıcının yerleştirilmesiyle yapılır. Metal taban malzemesi yükü destekler ve gö...

Ayrıntılara bakınız

MX2000-1 graphite embedded alloy bearing, MX2000-1 graphite scattered alloy bearing is an improved product of JF800 bimetallic bearing. It has the pre...

Ayrıntılara bakınız

SF-1W lead-free bearing is a new product developed based on SF-1X material according to international environmental protection requirements. In additi...

Ayrıntılara bakınız

SF-1T is a special formula product designed for high PV value working conditions of gear oil pump. The product has special advantages of fatigue resis...

Ayrıntılara bakınız

SF-2S oil-free lubricating bearing is an improved product of SF-2, with steel back matrix, sintered spherical tin bronze powder in the middle, and rol...

Ayrıntılara bakınız

Bize Ulaşın